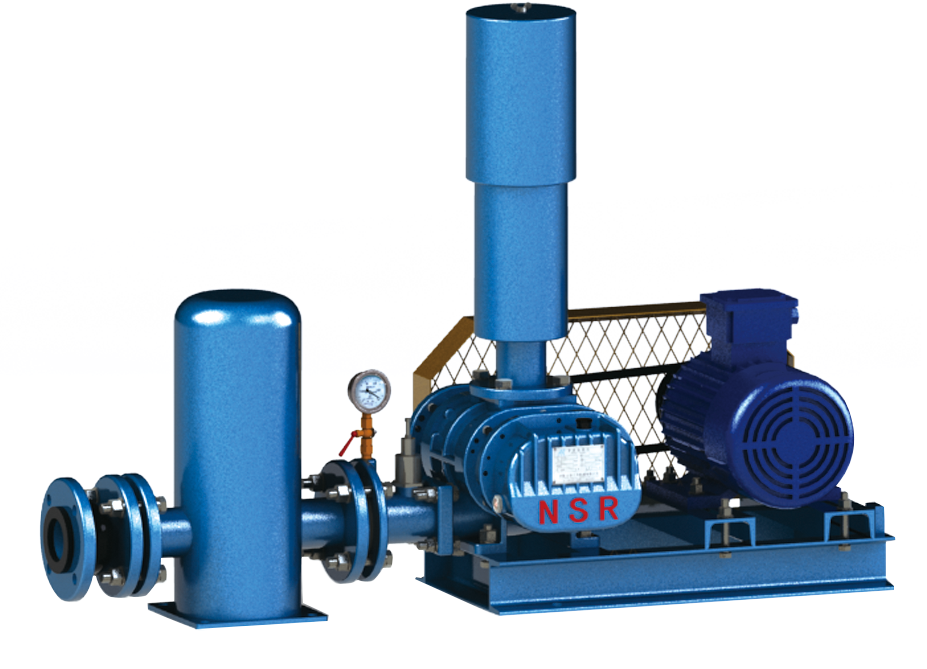

Operating Procedures for Roots Blower

2020-07-02

Summary

When using the Roots blower, the air volume of the blower should be adjusted according to the oxygen demand of the aeration tank. In case of abnormal phenomena such as sudden power failure of the fan and water and oil cooling system, measures shall be taken immediately to ensure that the fan does not fail.

When using the Roots blower, the air volume of the blower should be adjusted according to the oxygen demand of the aeration tank. In case of abnormal phenomena such as sudden power failure of the fan and water and oil cooling system, measures shall be taken immediately to ensure that the fan does not fail.

During the operation of the fan, the operator should pay attention to observe the wind pressure, oil temperature, oil pressure, air volume, current and voltage of the fan and motor, and record them in time.

In case of abnormal conditions that cannot be ruled out, the machine shall be shut down immediately.

Should always check the cooling, lubrication system is smooth, temperature, pressure, flow is to meet the requirements.

Preparation and inspection before 1. start-up

The voltage fluctuation value is within the range of 380V ± 10%, and the three-phase power supply cannot be short of phase. Instruments and electrical equipment should be in good condition, and electrical equipment that needs to be grounded should be grounded reliably. The connection between fan and pipeline and frame bolts should be tightened. Lubricating oil in the gear box should be according to the specified brand and added to the oil marking line. Turn the pulley 2~3 times by hand before starting to see if there is any abnormality; the outlet valve of the fan shall be closed in the shutdown state, and the vent valve shall be fully opened.

2. boot operation

Open the vent valve and air outlet valve; start the power supply, and if there is no abnormal phenomenon (such as metal friction sound, excessive current, etc.) after 30 seconds, gradually close the vent valve to make it operate normally; during normal operation, never close the outlet valve to avoid burst accident; if several fans are opened at the same time, one fan should be opened first, and the other one should be opened after the no-load operation is normal. Close the vent valve after normal no-load operation (30 seconds).

3. shutdown operation

Make records before shutdown, record the voltage, current, wind pressure, temperature, running time and other data; open the vent valve step by step; press the shutdown button; close the air outlet valve.

4. inspection of fan

After the normal operation of the fan, one hour inspection, every 2~3 hours a meter reading records (voltage, current, wind pressure, temperature, etc.). During the inspection process, pay attention to whether the sound of the fan is normal, and there should be no friction impact sound during operation. If there is any abnormality, stop the machine immediately for inspection.

Maintenance of 5. fan

Do a good job of routine maintenance, the fan room should be kept clean, well ventilated, and the surface of the unit should be free of dust and grease. Regularly (monthly) check the tightness of each connecting bolt of the fan; After the initial operation or overhaul, the fan should replace all the lubricating oil in the oil tank after 48 hours of operation. Generally, the oil should be changed when the fan has been working continuously for more than 500 hours. The standby fan should be started for at least one hour a week, usually, the fan should be switched with the standby fan after 10 hours of operation to prolong the service life of the fan. Under normal circumstances, the fan is checked once every 500 hours, repaired once every 2000 hours, repaired once every 3000 hours, and overhauled once every 15000 hours.

Contact Us

E-mail:

sanniu888@126.com

Telephone:

400-6531-228/0086-531-83288777

Address:East Industrial Park, Xianggong Sub-district Office, Zhangqiu District, Jinan City, Shandong Province