Proper maintenance and maintenance makes the fan long service life

2020-07-09

Summary

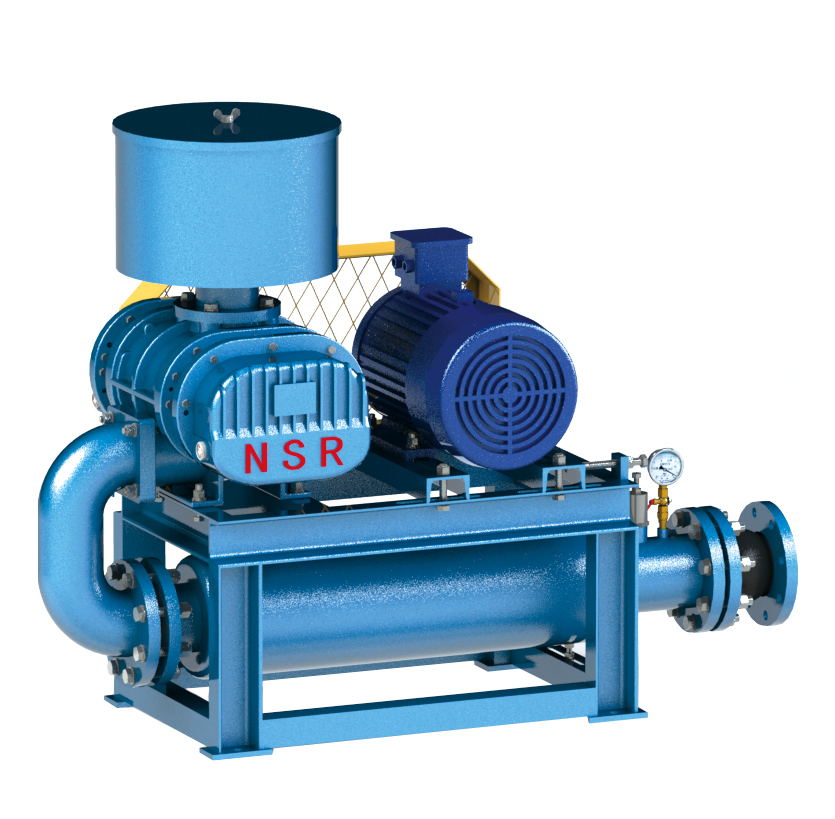

The fan gear adopts 20CrMnTi carburizing treatment, grinding processing, precision up to five, the tooth surface is more wear-resistant. The bearing adopts double-row roller imported bearing with large carrying capacity. The service life of the fan is thus increased. The fan output air is clean. The fan adopts a special structural design to avoid oil substances entering the casing, so the output air does not contain any oil.

The fan gear adopts 20CrMnTi carburizing treatment, grinding processing, precision up to five, the tooth surface is more wear-resistant. The bearing adopts double-row roller imported bearing with large carrying capacity. The service life of the fan is thus increased. The fan output air is clean. The fan adopts a special structural design to avoid oil substances entering the casing, so the output air does not contain any oil. All fan products, including accessories, have achieved standardized design and production, with good interchangeability and versatility, meeting the purpose of high quality, low cost and mass production. The safe operation and service life of the blower depends on the correct and regular maintenance and maintenance, and should pay attention to any accident seedlings. In addition to paying attention to the general maintenance procedures, the following points must also be emphasized:

1. Check the fastening of each part and whether the positioning pin is loose. If it is loose, it should be fastened.

2. Whether there is oil leakage inside the blower body.

3. There can be no scaling, rust and peeling inside the blower body.

4. Pay attention to whether the cooling condition of lubricating oil is normal, pay attention to the quality of lubricating oil, often listen to whether there is noise in the operation of the blower, and pay attention to whether the unit is working under non-conforming working conditions.

5. The overload of the blower is sometimes not immediately displayed, so pay attention to the changes in the intake and exhaust pressure, bearing temperature and motor current to determine whether the machine is operating normally.

6. When disassembling the machine, the matching dimensions of the machine shall be measured and recorded, and the parts shall be marked and oriented to ensure the assembly and maintain the original matching requirements.

7. The new machine or the blower after overhaul shall be put into operation according to the use steps. It is recommended to replace all lubricating oil after 8 hours of operation.

8. Under normal conditions, the lubricating oil must be replaced after 1000 hours of operation of the unit. The after-sales service of not changing the oil on time is not within the scope of free three guarantees.

9. Daily maintenance is very important, minor faults must be repaired before they are put into use.

Contact Us

E-mail:

sanniu888@126.com

Telephone:

400-6531-228/0086-531-83288777

Address:East Industrial Park, Xianggong Sub-district Office, Zhangqiu District, Jinan City, Shandong Province