Roots blower: what are the conditions for deformation and damage of Roots blower impeller

2020-11-30

Summary

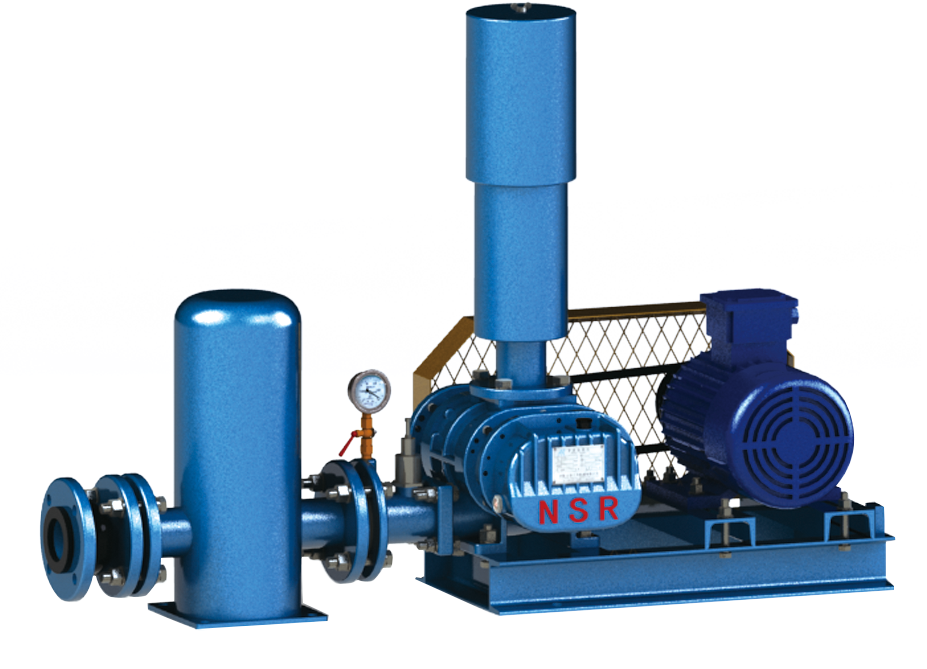

The equipment in the Roots blower industry is a frequently used mechanical equipment. Some problems will inevitably occur during operation, such as common impeller damage or deformation. Generally, there are two situations that can cause the impeller to deform and damage during the operation of the fan: one is that the fan runs for too long, exceeding its normal service life. The other is caused by sudden damage due to the failure of the design life. We will not say more about the former, just replace the impeller. The reasons for the latter case are: 1. The blade surface or rivet head is corroded or worn. 2. planning and leaf loosening.

Roots blowerThe equipment in the industry is often used mechanical equipment. Some problems will inevitably occur during operation, such as common impeller damage or deformation. Generally, there are two situations that can cause the impeller to deform and damage during the operation of the fan: one is that the fan runs for too long, exceeding its normal service life. The other is caused by sudden damage due to the failure of the design life. We will not say more about the former, just replace the impeller. The reasons for the latter case are: 1. The blade surface or rivet head is corroded or worn. 2. planning and leaf loosening. 3. The impeller production is unbalanced, and the vibration value exceeds the specified standard, causing the impeller to tilt or deform.

three cattleRoots blowerSolution:

1. If a single blade or rivet is damaged, the damaged blade or rivet can be replaced. If most of the blades or rivets are damaged, the impeller should be replaced with a new one.

2. If each rivet is loose, you can use a small punch to tighten it. If there is no effect, the new rivet can be replaced with the same material as the original rivet.

3. If the impeller is deformed and the deflection is too large, you can remove the impeller and correct it with a hammer, or place the impeller flat on the platform and press the edge of the side of the shaft disk until the impeller is corrected. It should be noted that after the impeller is corrected, the impeller needs to be balanced.

three cattleRoots blowerIt is a commonly used fan equipment, which is basically in a long-term operating state and will wear out more or less. Then, we need to carry out regular maintenance and inspection of the fan. The following are the regular inspection and maintenance standards for fans:

1. When the fan runs continuously for 3 to 6 months, please replace the grease once. It is recommended to fill 2/3 of the bearing space.

2. The fan runs continuously for 3 to 6 months, and carries out rolling bearing inspection to check the contact between the rolling bearing and the raceway surface and the tightness of the inner ring.

3. The Roots blower should be regularly overhauled to remove the dust inside the fan, and keeping the fan clean is conducive to the normal operation of the fan and the stability of the air pressure and air volume.

Contact Us

E-mail:

sanniu888@126.com

Telephone:

400-6531-228/0086-531-83288777

Address:East Industrial Park, Xianggong Sub-district Office, Zhangqiu District, Jinan City, Shandong Province