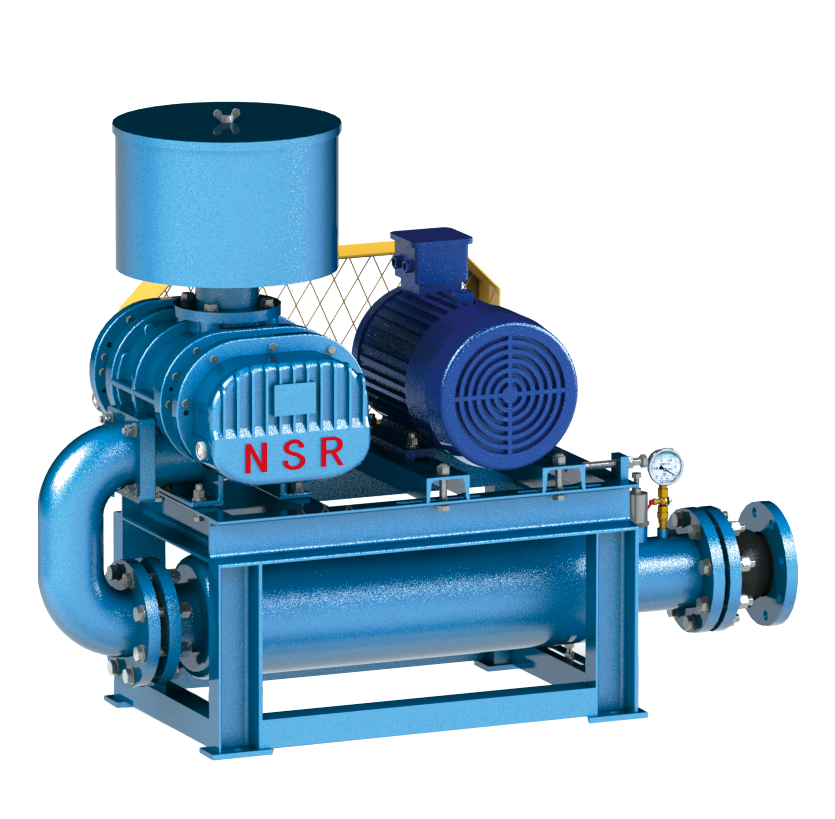

Roots vacuum pump: Roots vacuum pump unit ventilation process

2020-12-25

Summary

Roots vacuum pumps are widely used in metallurgy, petrochemical, paper, food and electronics industries. In order to better use the Roots vacuum pump and give full play to its high efficiency performance, the following, Shandong Sanniu Machinery Group Co., Ltd. will be used before the ventilation of the knowledge to do a certain explanation: 1. Air flows from the air inlet to the Roots vacuum pump unit to form a convection blower. During this process, the doors and windows near the equipment remain closed, and air is forced to flow into the workshop through the doors and windows on the side of the air inlet. The air is ordered. It flows into the workshop from the air intake, flows through the workshop, and then leaves the workshop from the workshop.

Roots vacuum pumpWidely used in metallurgy, petrochemical, paper, food and electronics industries. In order to better use the Roots vacuum pump and give full play to its high efficiency performance, the following, Shandong Sanniu Machinery Group Co., Ltd. will be used before the ventilation of the knowledge to do a certain explanation:

1. Air flows from the air inlet to the Roots vacuum pump unit to form a convection blower. During this process, the doors and windows near the equipment remain closed, and air is forced to flow into the workshop through the doors and windows on the side of the air inlet. The air is ordered. It flows into the workshop from the air intake, flows through the workshop, and then leaves the workshop from the workshop.

2. Thorough and effective ventilation, ventilation rate can be as high as 99%. Through specific engineering design, the ventilation speed and wind speed can be designed according to the needs, any high heat, harmful gas, dust and smoke can be quickly discharged from the workshop, and any problem of poor ventilation can be completely solved at one time, and after opening the workstation It can be solved within seconds.

3. The Roots vacuum pump unit discharges air to the outside to reduce the indoor air pressure. The indoor air becomes thinner. The characteristics of the water ring vacuum pump form a negative pressure zone. Due to the compensation of the pressure difference, the air flows into the room. In practical applications in industrial plants, it is installed centrally. On one side of the device, the air inlet is on the other side of the device.

Roots vacuum pump unit to do a good job in the ventilation process, can reduce the loss caused by resistance, improve efficiency.

Notes for Roots vacuum pump operation:

1. The Roots vacuum pump has a uniform acoustic response during operation, and there is no noise and no abnormal vibration during operation.

2. Pay attention to the motor load and the temperature rise of each part of the pump. Under normal circumstances, the high temperature rise of the pump should not exceed 40 ℃, and the working temperature should not exceed 80 ℃.

3. If oil leakage is found during work, please stop working immediately, and check and repair after pressure relief. After oil leakage is found, the Roots vacuum pump is not allowed to continue working or maintenance under pressure.

4. In the working process, the normal entry and exit of cooling water must be ensured.

Preparation before starting Roots vacuum pump unit:

1. Check whether the water level of the water tank of the flushing pump (front pump) exceeds 3/4 of the water tank. If it is not enough, please make up.

2. Check whether the water used in the water tank is clean. Prohibit the use of sewage containing silt, so as not to block the pipeline. Roots vacuum pump increases the wear of the pump impeller, increases the motor load and causes failure, which affects the service life of the flushing pump.

3. Check the lubricating oil level in the intermediate pump and the main pump body. It must be larger than 3/4 of the oil window. At the same time, check the color of the oil. If there are many Milky White or black impurities, please inform the technician to change the lubricating oil.

4. Check whether the circulating cooling water circuit of the intermediate pump and the main pump is in good condition, open the inlet and outlet valves of the circulating cooling water, and check whether the inlet and outlet of the circulating cooling water are normal.

5. Check whether the drain valve of the buffer tank at the bottom of the intermediate pump is closed.

6. Check whether the circuit of the Roots vacuum pump is in good condition and whether the instructions of the control cabinet are normal.

7. Check whether the starting pressure of the middle pump and the main pump of the roots vacuum pump electrode contact pressure gauge is normal (the starting inlet pressure of the middle pump is above 0.065Mpa, and the starting inlet pressure of the main pump is above 0.065Mpa). above 0.085Mpa).

8. After checking the above items and confirming that they are correct, you can start the Roots vacuum pump.

Contact Us

E-mail:

sanniu888@126.com

Telephone:

400-6531-228/0086-531-83288777

Address:East Industrial Park, Xianggong Sub-district Office, Zhangqiu District, Jinan City, Shandong Province